What are the challenges?

Foundries, steel production, and alloy processing have two common lighting design challenges:

- High ambient temperatures and corrosive atmospheres can accelerate the degradation of lighting equipment. Product selection is key.

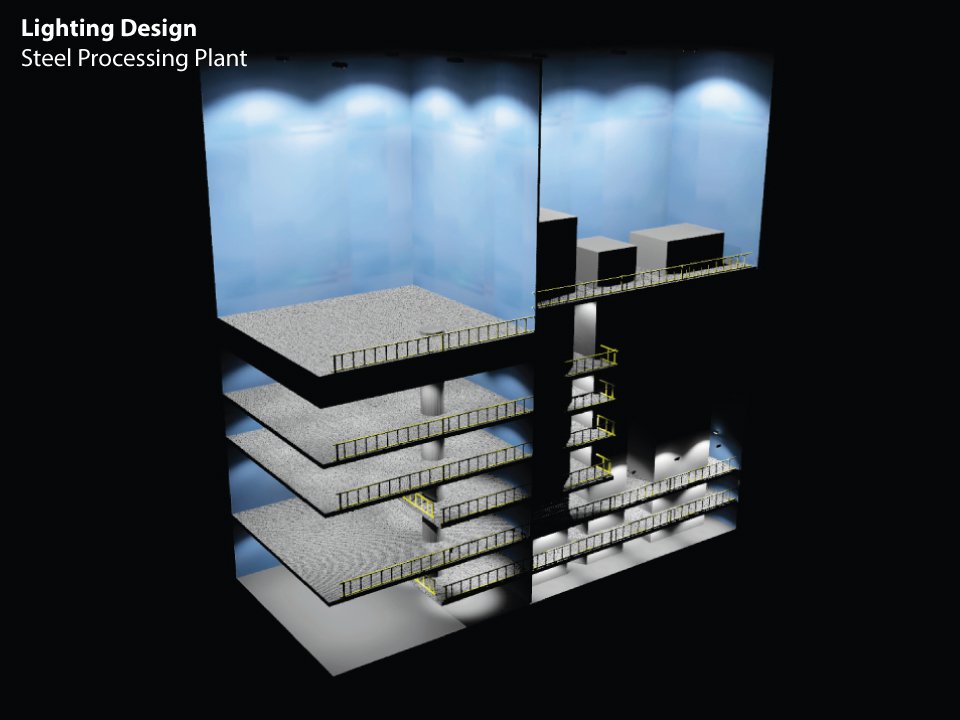

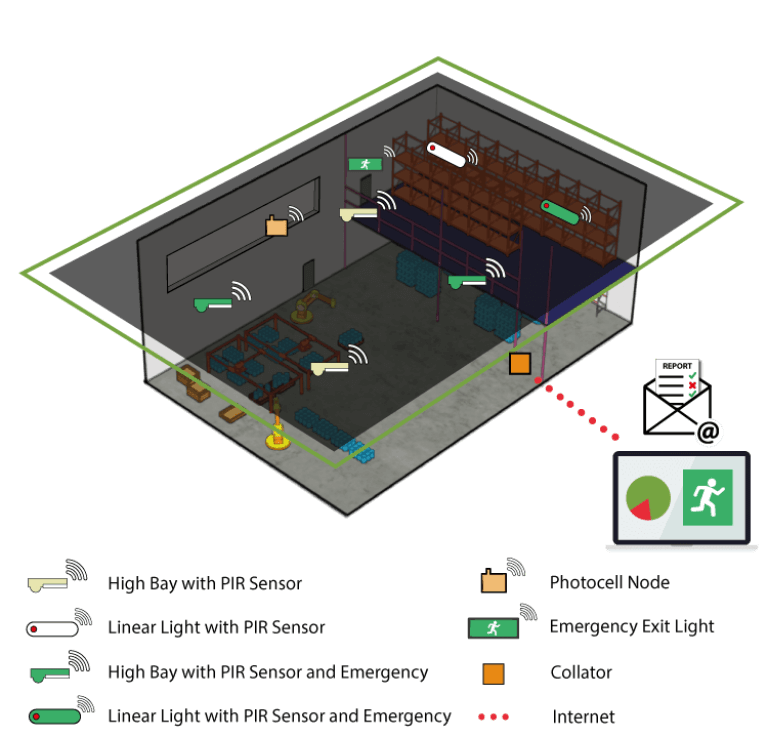

- Complex infrastructure needs to be appropriately illuminated to ensure it is a safe environment for personnel to operate in.

Why you benefit from partnering with Kellwood:

- Maintenance and replacement costs are minimised - the LEDs in our temperature resistant lighting range run below their maximum recommended drive currents, thereby improving product lumen degradation. Thermally isolated drivers include built-in thermal cut-outs and/or automatic power reduction to protect the LEDs and other sensitive electronics when temperatures exceed allowable limits. Lights automatically power back up to full brightness when temperatures fall back within the safe limit.

- Improve Health and Safety - our lighting design team can simulate lux levels across a wide range of areas (including casting, moulding, blasting, transit, tunnels, etc.) to ensure recommended lux levels are achieved.

Contact us to discuss your high temperature lighting project